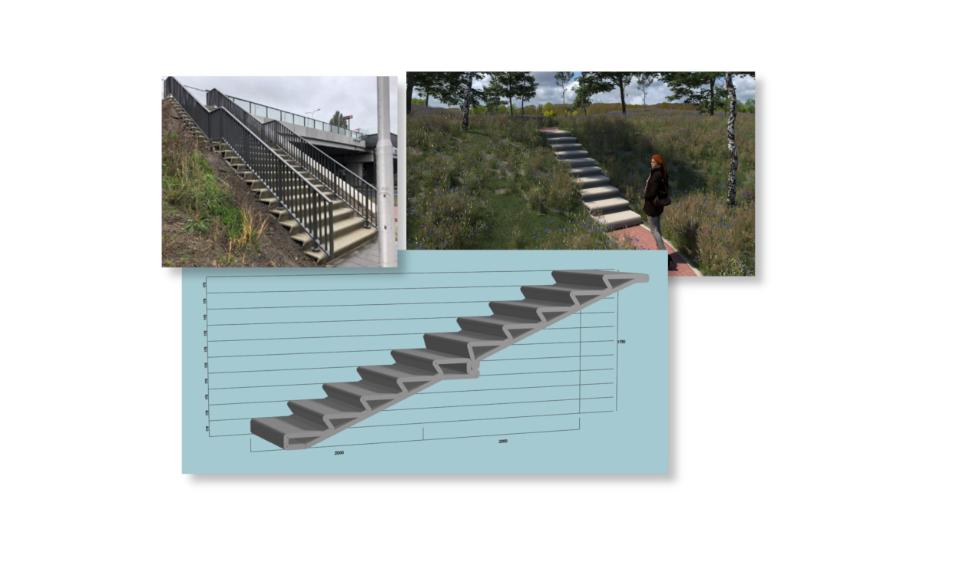

3D Concrete Printed Staircases

Weber Beamix and Witteveen+Bos

In collaboration with Weber Beamix, Witteveen+Bos facilitated the production of a custom-made talus staircase. All parameters of the staircase can be easily adjusted in the parametric design available on this website. This makes it possible to create your own staircase by entering your own parameters such as length, height and width.

Advantages

A 3D concrete printed talus staircase has several advantages. First, less material is needed than for a traditional staircase. In addition, the stairs consist of a single material and no formwork is needed. This ensures CO2 reduction.

Another advantage is that the embankment or dike does not have to be modified. The stairs can be placed directly on it without much other preparatory work.

Ordering

The ordering process is quick and easy and there are standard prices. From the moment the machine is turned on, the concrete staircase is made in a few hours, with almost no human intervention. To continue, a designer or engineer is not needed for the stairs, because all the requirements of the design have already been implemented in the parametric model of the staircase.

Do you want to know more or order a staircase right away? Click here.

3D Concrete Printing

Concrete is poured in layers to produce structural elements for buildings and infrastructure projects.

Want to know?

Marijn generates impact through innovation such as digitalisation and 3D concrete printing in the construction industry. He was the winner of the 2020 Cobouw Young Talent Award.