Housing construction in Singapore with 3D concrete printing

Housing and Development Board Singapore

Housing is in high demand in Singapore. Housing and Development Board (HDB), Singapore's public housing authority, is responsible for developing 80% of the houses. HDB initiated a research project to investigate the potential application of 3D concrete printing, with the aim of creating a production method that improves construction productivity and reduces dependence on foreign labour. Witteveen+Bos collaborated on this with Nanyang Technological Universities(NTU) and Robin Village.

Conventional construction methods

Designing and manufacturing concrete building elements using the conventional method of prefabrication has several disadvantages. It is a time-consuming process and requires skilled personnel. Moreover, the moulds used are thrown away, which leads to material waste.

3D concrete printing

Building using 3D concrete printing combines digital Building Information Modelling (BIM) technology with additive production techniques. This gives a lot of freedom of form; so shapes can be made that were previously impossible to make using traditional construction methods. In addition, no mould or formwork is needed. As a result, less material is wasted.

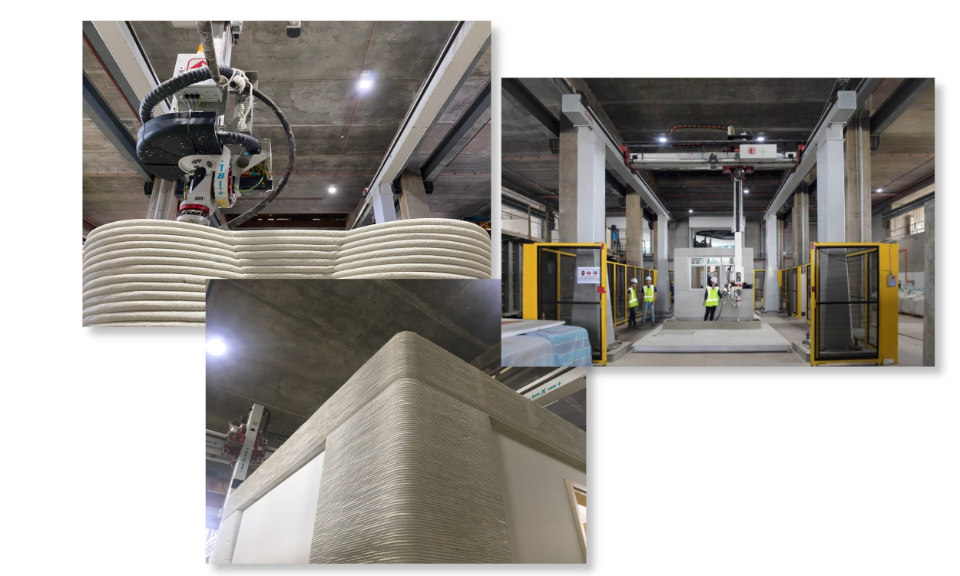

Largest 3D concrete printer in Southeast Asia

The 3D printer has been installed at the HDB Centre of Building Research (CBR). It is the largest 3D concrete printer in Southeast Asia. It can print parts up to 9 metres long, 3.5 metres wide and 3 metres high. Witteveen+Bos advised on the printer's specifications. Among other things, two room-high 3D concrete printed components were made with this printer, the first in the world of 3D concrete printing.

Major time savings through new construction process

The entire construction process of the 3D concrete printed room, including manually inserting steel reinforcement bars into the structure and installing windows and a door, took about six days. By comparison, it would take more than two months to build a similar room using the conventional method of prefabrication. Manufacturing the prefabricated form alone takes two months.

3D concrete printing

Concrete is poured in layers to produce structural elements for buildings and infrastructure projects.

Want to know more?

Marijn generates impact through innovation such as digitalisation and 3D concrete printing in the construction industry. He was the winner of the 2020 Cobouw Young Talent Award.