Integrated 3D Pipeline Design

Several public and private parties claim the underground to put their assets there. After all, the underground space is the place for everything you don't want to see, like sewers, water pipes and electricity cables. With energy transition requiring space for cables for electricity or heat networks, this underground space is becoming increasingly crowded. Integral 3D Pipeline Design offers help.

Applied by Schiedam

Complexity of the subsurface

Sewer operators are busy renewing outdated sewers, enlarging existing sewer systems and disconnecting and buffering rainwater (underground). In doing so, climate adaptation has an impact on the subsurface. In short, the subsoil, especially the first user layer of a few metres deep, is becoming increasingly full. For sustainable soil management, we need to take a good look at the current and future underground infrastructure, and for acceleration we need to identify linking opportunities.

Integrated 3D Pipeline Design

Witteveen+Bos is experienced in 3D design of cables, pipes and sewers. We have built up templates, scripts and datasets that make design efficient. This has been brought together in Integrated 3D Pipeline Design. This tool works with datasets of existing cables, pipes, groundwater levels, locations of existing trees and manages the intersections between them. With this, a complete underground system can be designed and dimensioned within a short time. Now you can see at an early stage where there is space in the subsurface for new pipes to be inserted.

Click on the video to view the visualisations of the tool.

Clash detection

Designing sewer systems and other underground infrastructure, such as cables and pipes for gas, water, data and electricity, is now mostly done in 2D, but that has his limitations. With Integrated 3D Pipeline Design, clashes with existing cables, pipes and other objects in the subsurface, such as tree roots, underground rubbish containers and charging stations, can be detected better and earlier. This reduces repair work and costs during execution.

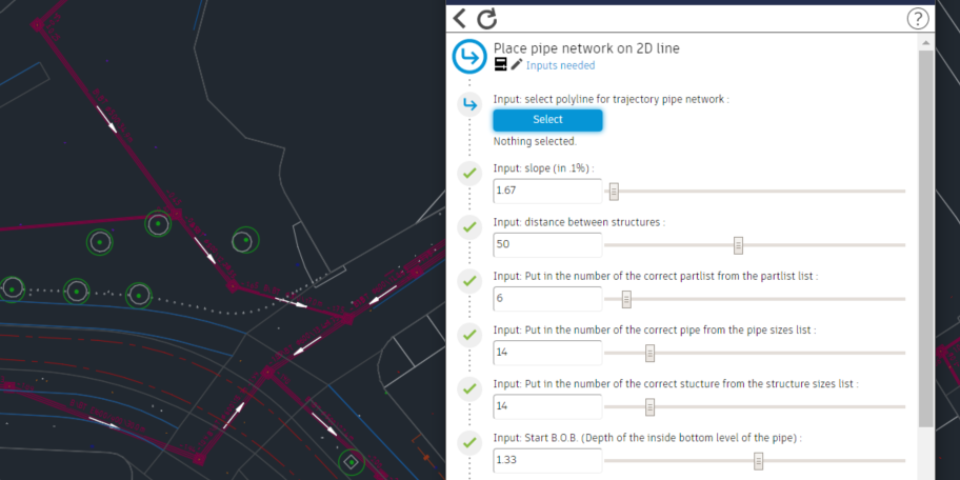

Parametric design

Using parameters (desired depth location, diameter, trench width, etc.), feasible and safely implementable variants are developed. All parameters comply with national standards and guidelines. Integrated 3D Pipeline Design provides the pipeline with the minimum required ground cover and calculates the most optimal location and height. The tool also provides the desired execution technique and corresponding excavation profiles for the underground infrastructure. This ensures less excavation, less inconvenience and is therefore cost-efficient. The model can be easily adjusted during the design process, which makes the design flexible. The tool then calculates the (tender) quantities to set up the cost calculation.

3D Sewer design

For sewer design, we go one level deeper. Integrated 3D Pipeline Design links calculation (dimensioning) and drawing (3D design). Using smart scripts, we automatically design and dimension a system of manholes and pipes. With the link between design software (Civil 3D) and modelling software (infoworks), we calculate the sewer system in terms of the normative climate rainfall or capacity. Based on the results of the calculations, the design is automatically updated, and fitted into the road profile. This process is not only much more efficient but also less error-prone.

Why Integrated 3D Pipeline Design?

Less repairs and failure costs

Early and qualitative clash detection saves costs.

Less excavation work

The tool calculates the most optimal location and height of the cables and pipes, thereby excavation work will be reduced.

Flexible design

The model is easy to adapt during the design process.

Want to know more?

Rick uses digital tools to do his work within urban infrastructure as quickly and efficiently as possible.